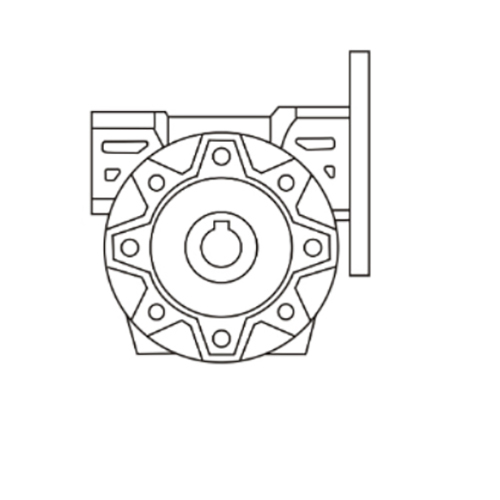

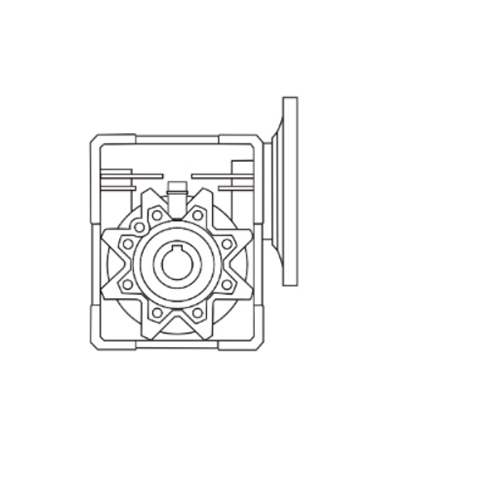

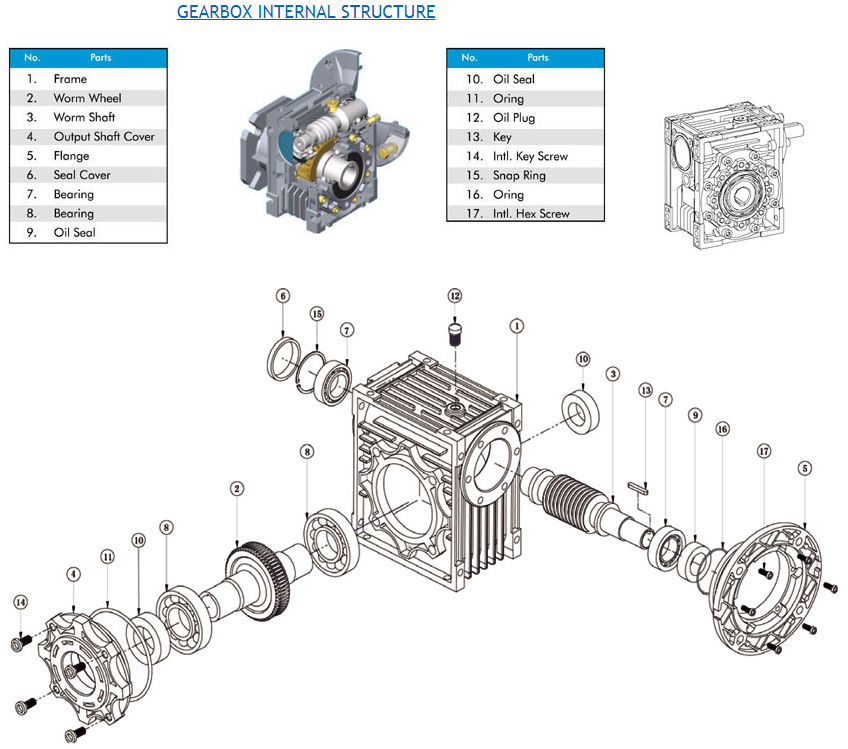

BL Series Industrial Worm Gearbox

Price 5000 INR/ Unit

MOQ : 1 , , Unit

BL Series Industrial Worm Gearbox Specification

- Gear Type

- Worm Gear

- Material

- Cast Iron, Alloy Steel

- Processing Type

- Precision Machined

- Gear Tooth Profile

- Worm

- Gearing Arrangement

- Worm

- Direction

- Double Direction

- Output Torque

- Up to 3500 Nm

- Rated Power

- Up to 50 kW

- Input Speed

- 1400 rpm (max)

- Output Speed

- 14-280 rpm

- Voltage

- 220 V / 380 V

- Efficiency

- Up to 95%

- Lubrication

- Oil Bath

- Ambient Temperature Range

- -10°C to 50°C

- Mounting Type

- Foot / Flange Mounted

- Reduction Ratio

- 5:1 to 70:1

- Center Distance

- 30 mm to 250 mm

- Housing Protection

- IP55

- Noise Level

- Low

- Application

- Industrial Machinery, Conveyors, Material Handling

BL Series Industrial Worm Gearbox Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1 , , Unit Per Day

- Delivery Time

- 7 Days

About BL Series Industrial Worm Gearbox

BL Series Industrial Worm Gearbox is used in low torque applications like conveyors, rolling machine etc. It is widely demanded by clients owing to tensile strength, superior functionality, unmatched resistance to corrosion. It is manufactured with the use of quality approved raw material and the state of the art technology under the supervision of skilled professionals. Moreover, the offered BL Series Industrial Worm Gearbox is available to the patrons at nominal rates.

Precision and Durability Combined

With components made from cast iron and alloy steel, the BL Series gearbox undergoes precision machining to guarantee consistent performance over time. Its worm gearing arrangement ensures smooth power transmission and high shock resistance, ideal for heavy-duty industrial tasks.

Versatile Mounting & High Protection

Choose either foot or flange mounting to suit your installation requirements. The IP55-rated housing protects the gearbox from dust and water jets, making it suitable for use in harsh industrial environments, including conveyors and material handling setups.

Optimized for Industrial Efficiency

Operating at input speeds up to 1400 rpm and supporting reduction ratios from 5:1 to 70:1, the BL Series maintains efficiency up to 95%. With output torque up to 3500 Nm and power ratings up to 50 kW, it handles a broad range of mechanical loads with ease.

FAQ's of BL Series Industrial Worm Gearbox:

Q: How does the BL Series industrial worm gearbox enhance equipment performance?

A: The BL Series gearbox delivers up to 95% efficiency and high output torque (up to 3500 Nm), ensuring machinery operates smoothly and reliably even in demanding conditions. Its low-noise operation and precision-machined gears reduce wear, minimizing downtime and maintenance.Q: What mounting options are available for this gearbox, and how do I choose?

A: You may select either foot-mounted or flange-mounted configurations, depending on your installation space and equipment design. Foot mounting provides stability for floor installations, while flange mounting is ideal for more compact or vertical setups.Q: When should oil bath lubrication be checked or replaced in this gearbox?

A: It's recommended to inspect the oil level and condition at regular intervals, such as every 1,000 operating hours or as directed by your maintenance schedule. Oil bath lubrication reduces friction and wear, ensuring the gearbox maintains its low-noise and high-efficiency performance.Q: Where is the BL Series industrial worm gearbox commonly used?

A: This gearbox is widely used in industrial machinery, conveyors, material handling systems, and similar applications. Its robust construction and versatility make it suitable for heavy-duty and continuous operations, particularly in factories and processing plants.Q: What is the benefit of IP55 housing protection for this gearbox?

A: IP55 protection ensures the gearbox is well-guarded against dust ingress and water jets, extending its operational life and reducing the risk of mechanical failure in challenging industrial environments.Q: How does the gearbox handle bidirectional operation?

A: The worm gear arrangement is designed for double direction use, allowing the output shaft to rotate in both directions with consistent efficiency. This feature enhances flexibility for applications requiring forward and reverse motion.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Worm Gearbox Category

BL Series MS Worm Gearbox

Price 5000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 415V AC

Material : Other, Mild Steel

Gear Type : Other, Worm Gear

Gearing Arrangement : Worm

BL Series Worm Gearbox

Price 5000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 380V

Material : Other, Cast Iron

Gear Type : Other, Worm Gear

Gearing Arrangement : Worm

BVF SERIES

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Material : Iron

Gear Type : Worm Gears

Gearing Arrangement : Worm

BW SERIES

Minimum Order Quantity : 1 Piece

Voltage : 220440 Volt (v)

Material : Iron

Gear Type : Worm Gears

|

MAA INDUSTRIAL MARKETING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry